A Guide to How Elevator Manufacturers Design and Build Lifts

Essential to creating accessible indoor spaces, elevators are a must-have for both businesses and tall residential properties across the globe. To create these lifts, property owners will employ the services of elevator manufacturers. This article offers insight into their processes, explaining everything you need to know about elevator design and manufacturing.

The Basics of Elevator Design

To create an elevator that operates effectively, manufacturers will often need a team dedicated specifically to the lift’s design. From the buttons used to operate the lift to the material the elevator car is made of, each component of an elevator requires careful consideration. Read on to discover the key elements of lift design in more detail.

Overall Design

Arguably the most important part of the design process is to determine how the elevator will look. Elevator cars and exteriors are made of many different components, each requiring thought for their design. For example, a manufacturer and designer will need to decide whether the elevator should have a mirror, and what that mirror should be made of.

Material

Another important design consideration elevator manufacturers need to think about is the material. Primarily, elevators are made of steel, as it is a strong and durable material that can withstand the weight and movement of the lift car. Other options for constructing elevator cars include glass, allowing the lift user a view of their surroundings as they travel between floors. Elevators will generally require multiple materials in their design, so it’s often simply about choosing the right combination for manufacture.

Assembly

For a design and manufacturer, they will need to consider which parts of the elevator will be assembled in their facilities, and which will be assembled on-site. This decision needs to be made carefully, as it will significantly impact how easy the installation process is.

Testing

The elevator will need to be designed for testability, making sure the manufacturer can adequately test its operation and make sure it is safe for use. Testing will be done throughout the design process, ensuring that even the most minor components are fully functional. This can prevent problems from arising later on, which in turn saves the manufacturer from delays.

Key Considerations for an Elevator Designer

When elevator designers start to design a lift for a project, there are many specific elements and factors they have to take into account. These considerations help the manufacturers to create an elevator that their clients will be pleased with and is safe for use. Below, you can discover the key aspects an elevator designer must consider as they create a lift system.

Safety

One of the most important things to consider is how safe the lift needs to be, including who it should be suitable for. Lifts are typically designed with accessibility in mind, making it important for elevator designers to ensure the final product is safe for every user.

Capacity

When designing a lift, capacity is an aspect that must be thought about. Without considering capacity, lifts can either be unnecessarily large, wasting precious floor space, or too small for the number of people waiting to use them, resulting in long wait times and delays. When deciding which capacity will be appropriate for an elevator, designers will need to take into consideration the amount of foot traffic in a building, as well as the number of inhabitants or employees.

Energy Efficiency

If the elevator offers poor energy efficiency, it can often cost the client a lot of money in the long term, making it far from preferable. Similarly, high elevator energy consumption can contribute to harm to the environment, making it far from an eco-friendly option. When designing an elevator, elevator engineers will need to consider the wants and needs of the client when it comes to energy consumption.

Aesthetics and Comfort

Loud elevators can be unpleasant for the user, while bumpy rides can be both frightening and uncomfortable. When designing a lift, the manufacturers will take into account how enjoyable their design is to use.

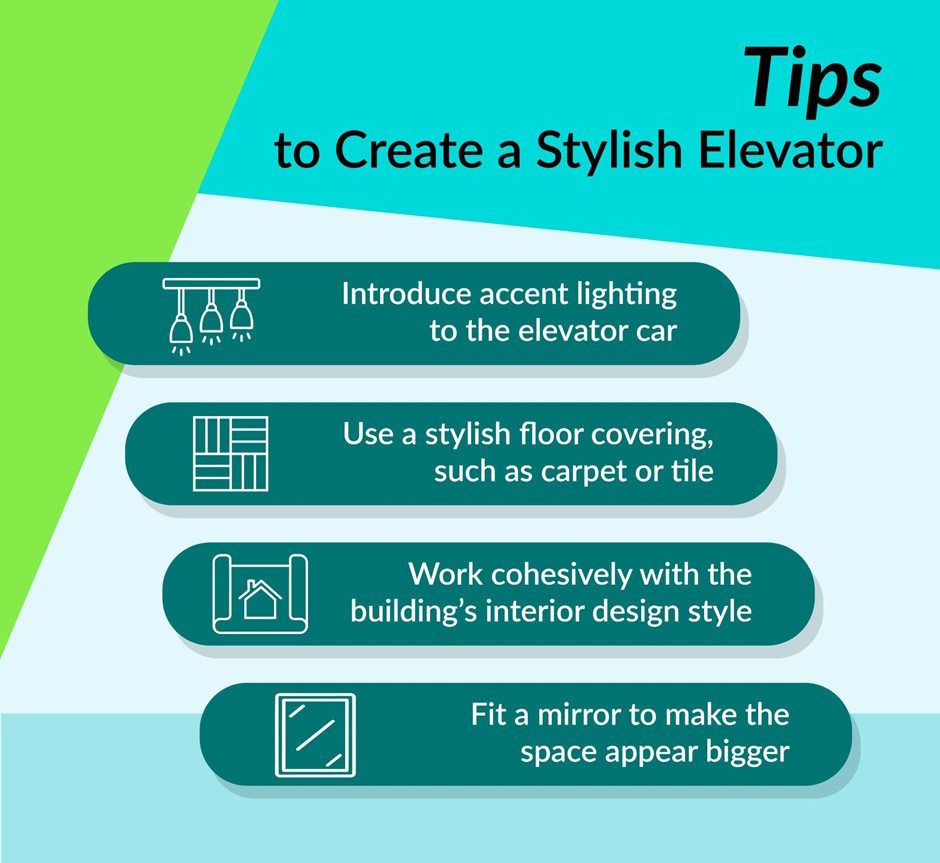

How a lift looks is also highly important to designers and their clients. Aesthetics can impact the impression an elevator gives. An unstylish elevator, therefore, can be offputting for visitors to a building. An outdated lift can often negatively impact the visitor’s overall experience and impression of a company, making it important for designers to consider how their lift looks alongside how it functions.

Maintenance Requirements

When creating an elevator, the designers need to consider how the final product will need to be cared for. These experts will ensure that the internal systems are accessible to those repairing the lift, making sure fixes are as simple and quick as possible.

Step-by-Step Process of Elevator Manufacturing

From the initial stages of conceptual design and engineering to the selection of high-quality materials, there are many phases involved in the manufacture of an elevator. This section will explain the step-by-step process of elevator manufacturing, giving you a complete overview of how the system works.

Concept

To start, designers will come up with a concept for an elevator. This stage of the manufacturing process will include gathering key information from the client. The team will need the specifics before creating an elevator, from the number of floors the lift will need to reach to the expected daily foot traffic.

Design

Using sketches and computer programs, an elevator manufacturer will be able to start designing the lift from the concept. The team working on this project will determine and consider the dimensions of the elevator and the materials that will be used. Key decisions will need to be made at this time, so often the team will need to communicate with the client to make sure they approve.

Prototype

To make sure the concept and design are executable, the manufacturing team will make a prototype of the elevator. This prototype will typically not be used in the actual building, but in a controlled environment which is designed for testing purposes. Here, the team can make sure the elevator meets the requirements.

Manufacture

Once it has been determined that the lift will operate effectively and safely, the team can start to manufacture the final product. Each component and system that will make up the final product will need to be crafted by professionals, including the lift’s electrical system. During this process, each part will be inspected to make sure it is of a high quality and is therefore suitable for use in the final product.

Installation

The final stage of elevator manufacturing is to install the elevator. A team of professionals in elevator installations will transport the parts to the site, allowing them to easily access the manufactured pieces they need. These can then be fitted into the property, as well as connected, resulting in a fully operational elevator.

How to Choose the Right Elevator Engineers

As elevators are a substantial investment, businesses need to choose a designer that will help them achieve their dream lift. Read on to find out some key factors to consider when choosing a lift manufacturer, from their past reviews to experience.

Experience and Expertise

It’s often worth exploring how much experience a business has, as this can indicate that they have had a chance to grow their expertise and face various challenges. Manufacturing a safe elevator requires in-depth knowledge, and experienced elevator engineers are typically more likely to have this.

Customer Service

As a lift design and installation is a lengthy and costly process, it’s important to ensure you can trust your manufacturing team. When speaking to a potential manufacturer, take into account how you are spoken to and treated. Quick responses to your queries, for example, can often indicate that the business will be attentive in their care, which is highly important if you have a problem further down the line.

References and Testimonials

Finding reviews from past clients who have hired the business for a similar service can often give you an idea of what to expect from the team. Glowing testimonials are often a very good sign, demonstrating that the team will provide attentive services and a high-quality installation.

Our Lift Services in Scotland

If you’re looking to make your property more accessible and need an elevator manufacturer to make it happen, our team at ADL Lift Services are here to help. We offer professional lift design services, allowing us to custom-craft elevators that are perfectly suited to our clients. Whether you’re looking for an eco-friendly lift solution or an elevator with enhanced safety features, our team of experts can make it happen.

To explore our complete range of lift services, please visit our website. Here, you will find everything you need to know about us, including some case studies of our previous work. Alternatively, to get started on your journey to a more accessible building, please get in touch with our team directly today.