What To Include On An Elevator Maintenance Checklist

Carrying out regular maintenance, inspection and tests on your elevator system are vital in reducing the risk of a serious incident, breakdown or even potential injury, ensuring both the efficiency and safety of your lift. When carrying out said checks, you should consider carrying a checklist of the critical components that require inspection, and here, we highlight the most important examinations worth performing.

Inside The Cabin

The first inspection carried out during elevator maintenance is inside the lift cabin itself. This is the interior of the lift responsible for carrying goods or passengers and requires safety, practicality and comfort in equal measure. When inspecting the lift cabin, it’s important to:

● Check the doors are able to open and close freely without interruption or obstruction.

● Assess the interior for signs of damage on the ceiling, handrails and walls.

● Locate and replace any burnt-out lighting fixtures, including in the control panel.

● Ensure the emergency stop is illuminated and in working order.

● Confirm the emergency phone is in operations and connects quickly with the emergency services.

Outside The Cabin

A series of checks and inspections must now be performed on the exterior of the cabin, this will typically include the following:

● Replacing broken lighting fixtures on the exterior control panel (call button).

● Performing an inspection of the door panels and clearances.

● Testing the smoke detector and fire alarm system is in operation.

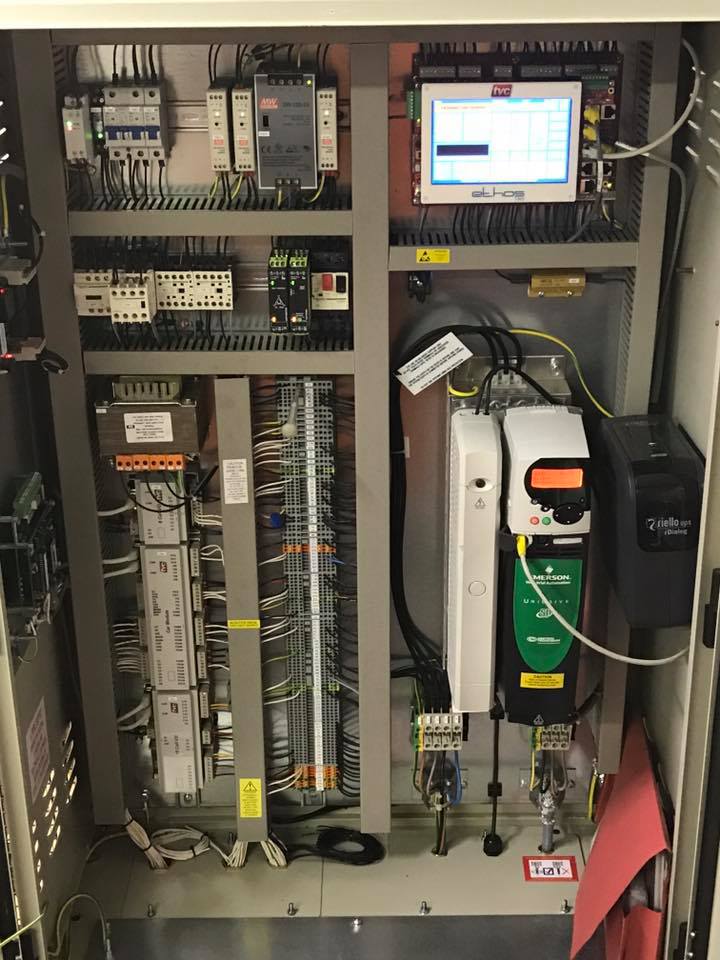

The Machine Room

An area set aside for the elevator equipment that powers the drive, the ‘machine room’ is essential for the function of your elevator system. In simple terms; consider the lift cabin as the body and the machine room as the brain. Examinations on the machine room should include:

● Ensuring oil levels are correct and check cable systems are effectively lubricated and undamaged.

● Performing a thorough examination of your electrical wiring for any obvious signs of fraying or faults.

● Removing obstacles that may interfere with access to the equipment.

● Providing adequate headroom for technicians.

On Top

When carrying out tests, checks and inspections on top of the lift car, it’s important to:

● Check the emergency exit hatch is of the necessary accessibility.

● Perform a test of the brakes and inspect the mechanism and fluid levels.

● Inspect the cables for signs of wear and tear.

● Analyse the hoistway for signs of vandalism or rodent interference.

In The Pit

At the bottom of every elevator shaft is the pit. The pit area is typically dark, dirty and often ignored, but still requires regular inspection to ensure it’s safe and in good condition, such as:

● Ensuring the pit area has the appropriate space for access in case of breakdowns.

● Inspecting the pit to make sure the pit has the necessary clearance.

● Checking the frame of the lift car for any signs of damage or wear.

At

ADL Lift Services, we understand the importance of personalised service and the right lifts for your needs. Our team of lift manufacturers in Scotland provide some of the very best services across the country, with expert knowledge, years of experience and unbeatable customer service. If you’re stuck with a problem with your lifts, we have a solution to help.

Contact us today!