Lift Maintenance Tips: 5 Common Lift Problems And How To Solve Them

As our buildings and skyscrapers reach new heights, you’d be forgiven for wanting to jump in an elevator rather than take 10 flights of stairs. Lifts really have revolutionised transport within buildings, allowing for fast and easy travel between floors without relying on stairs. They are also required for most multi-floor buildings thanks to the Equality Act 2010, requiring businesses and organisations to make ‘reasonable adjustments’ to their premises in order to facilitate disabled access.

However, for all the good that a lift can bring to a

business, there is still a pervasive, yet somewhat misplaced fear of them failing.

Of course, being trapped in a box suspended above multiple floors isn’t ideal.

Yet, you may be surprised to learn that lifts are one of the safest modes of

travel, being 20 times safer than the seemingly innocuous escalator. Although

travelling via lift is extremely safe, with a variety of fail-safes in place to

protect both passengers and technicians, they are still prone to malfunctions

from time to time that can lead to an uncomfortable ride or even a breakdown if

left unchecked.

With this in mind, it’s important to have at least some kind of understanding

around what some of the most common lift malfunctions are, giving you ample

time to contact a lift repair service.

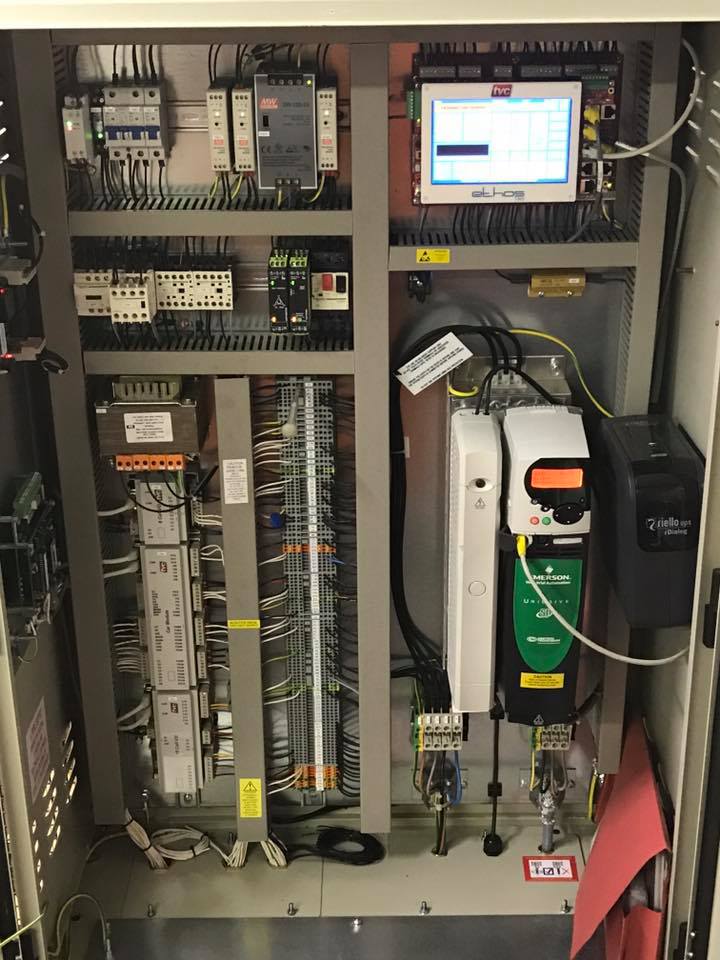

Arguably one of the most distressing problems on this list for passengers riding the lift, a power failure can be a scary experience. From flickering lights to a complete breakdown of the unit in question, a power failure can lead to a lengthy operation to free any passengers and get your lift back up and running. Of course, a power failure can be down to an outage affecting the city, however, the most common issue may be down to the motor. Lifts use a significant amount of power in order to function and can put a fair amount of strain on the building’s utility system. Changes to the system’s voltage is a usual culprit to this problem, affecting the motor and even potentially damaging the elevator itself.

If your elevator has a history of motor failures, it may be time to conduct a power quality survey. This process will allow a technician to test for ‘clean’ electrical energy running through your system and to determine your lifts Overall Equipment Effectiveness (OEE). This is usually done through Infrared thermography, giving the repair technician a clear image of any power fluctuations or faulty components in the motor.

In layman’s terms, a sheave is a pulley with a grooved wheel designed to hold a rope or belt. It is an essential component to the normal functioning of a lift, connecting the ropes to the car. Over time, the constant rubbing of ropes from day to day use can begin to wear the sheaves down, making them uneven. Further wearing places extra weight on the ropes which then exacerbates the issue, potentially leading to the rope slipping from the sheave.

Luckily, there are ways this issue can be fixed, namely by either regrooving or replacing the sheave in question. Because of this, it is imperative to regularly check the sheave’s groove profiles in order to catch any problems before they get worse. If the sheave is still in good condition, regrooving is the usual fix of choice and can be carried out by a licenced repair operative. If the problem persists, however, it may be time to look into replacement options.

Like most machines, the components in a lift need to be well lubricated with clean oil in order to run properly; this is especially important for hydraulic models. However, through the day to day use of the lift, wear can occur which can break off tiny metallic particles. These particles can then infiltrate the oil, interfering with the efficiency of the lift. These issues can reveal themselves in a variety of ways, from a foul-smelling odour permeating the lift car to problems with lift levelling, causing the car to stop before reaching its intended floor.

To counteract this issue, the best course of action is to conduct an oil analysis. The test will inspect oil samples used throughout the lift system examining them for impurities. An influx of bronze, for example, is usually a sure sign of a problem and your oil will likely need to be replaced.

Hearing unusual noises when the lift is in transit is never going to fill you with confidence, especially when it could be the sign of a larger problem. Malfunctioning bearings is one of the most common problems that can affect a lift system and can be irritatingly loud if left unchecked. This can be a simple issue such as a loose or worn out part, however, if the bearings are damaged, they can cause excess vibrations in the motor which can potentially lead to a breakdown.

A variable frequency drive can help to adjust the power running through the motor, thus lessening the noise from the bearings. However, this does have the side-effect of creating common mode current, a byproduct which can cause serious wear to the bearings. An inductive absorber can rectify this issue, yet it may be best to contact a technician who will have the knowledge to fix the issue properly.

Another common issue is a misaligned motor drive, which can cause a variety of problems. When a piece of equipment is connected to the motor drive, shaft alignment is vital to ensure proper operation. If the alignment is even slightly off, the motor bearings will begin to wear at a significant rate, causing many of the problems stated above.

Again, as this is an essential repair, it is imperative to have a technician on call to inspect the damage. Although misalignment, if bad enough, can be spotted by simply enlisting a straight edge and a piece of string, laser technology can also be used to give an even more accurate image of alignment, meaning even minor faults can be detected.

The importance of regular elevator maintenance

As you can probably tell, the above issues can become serious if left unchecked, putting passengers and technicians at risk. However, the easiest way to counteract these issues is to catch them before they can get any worse. Having a lift company carry out regular servicing on your unit will ensure your elevator remains fit for use, giving you the peace of mind you need.

It is important, however, that you ensure that you’re working with a reputable name within the elevator industry. Luckily, there are a variety of governing bodies which monitor lift company practice such as the British Assessment Bureau and the Lift and Escalator Industry Association; if you’re chosen technician is a certified member of one of these, it is a sure sign of a quality job.

ADL Lift Services - Scotland’s premier lift maintenance company

If you are in ownership of a lift, you likely already know how important it is to the smooth running of your building which is why, when breakdowns occur, they can cause genuine problems to your day to day operations. With this in mind, it is essential that you have an expert in lift repairs and servicing at hand in case of any emergencies.

At ADL Lift Services, we have a combined experience of 80

years in the lift industry and have all the skills and knowledge necessary to

keep your lift running smoothly. Operating throughout Scotland, we offer

24/7-365 days a year emergency cover for all of our customers so you’ll never

be caught out without help.